Asphalt Mixing Bitumen Equipment

- TTM

- QUANZHOU,新麻豆视频

- 30-35 DAYS

- 20 SETS PER MONTH

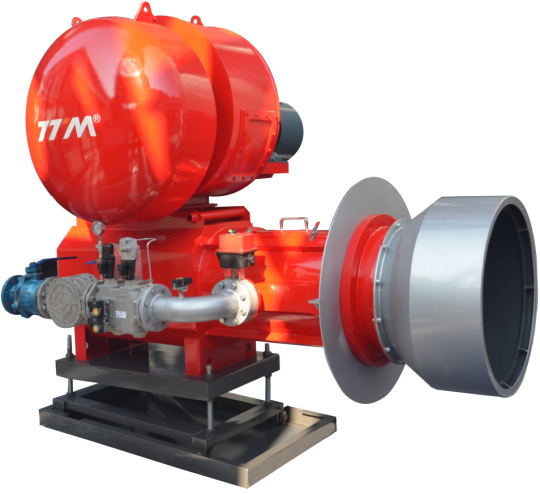

The burner details:

The low-pressure burner is designed for the dryer drum with digital control on air/oil ratio and frequency, to ensure the better flame as per drum, to reduce oil consumption greatly. The burner control is integrated with plant control, easy to operate, safe and reliable. Suitable for diesel, heavy oil and natural gas.

----- 160t/h asphalt paving equipment ------

1. Type: GLB-2000

2. Production: 160t/h

3. Hot Agg Bin: 28m3

4. Capacity: 2000 kg

5. Finished Storage Bin: 50/100/200/300 t

-----------Main Feature------------

1. The feeding belt is designed with baffles, which makes material feeding system steady and smooth.

2. The optimized flights structure of drying drum makes the drying system more effective and stable

3. The hot elevator adopts the double Gall's chain for hoisting, which not only prolongs the service life of the hoisting machine but also improves the running stability

4. The linear-mode screen driven by imported vibrator improves the screening efficiency and reduces the failure rate of plant

5. Large capacity hot aggregate bin makes operation more convenient

6. Our unqiue designed paddles and the powerful mixer allow the mixing operation easier, effective and reliable

7. Dual-stage dust removal system and negative pressure dustproof design make our asphalt mixing plant ecofriendly and economical

8. The computer-controlled system, auto/manual switchable, and auto self-diagnosis program makes the operation easy and safe

9. Overall modular design makes the transportation and installation more convenient and fast

10. The RAP interface is reserved for upgrade hot RAP facilities.

GLB Series (bottom type finished storage silo)

Featuring small land occupation area, low failure rate and is highly environmental friendly. It is suitable for various construction projects.

GLB Series(bottom type finished storage silo) | |||||

Type | Production | Hot Agg Bin | Capacity | Finished Storage Bin | Weighing Accuracy |

GLB-600 | 48 t/h | 7 m3 | 600 kg | 30 t |

础驳驳谤别驳补迟别:±0.5% Filler :±0.25% Bitumen :±0.25%

|

GLB-800 | 64 t/h | 7 m3 | 800 kg | 30 t | |

GLB-1000 | 80 t/h | 12 m3 | 1000 kg | 50 t | |

GLB-1200 | 96 t/h | 12 m3 | 1200 kg | 50 t | |

GLB-1500 | 120 t/h | 25 m3 | 1500 kg | 50t/100t/ 200t/300t | |

GLB-2000 | 160 t/h | 28 m3 | 2000 kg | 50 t/100t/ 200t/300t | |

GLB-2500 | 200 t/h | 50 m3 | 2500 kg | 100 t/200 t/300t/400t | |

GLB-3000 | 240 t/h | 50 m3 | 3000 kg | 100 t/200 t/300t/400t | |

GLB-4000 | 320 t/h | 75 m3 | 4000 kg | 100 t/200 t/300t/400t | |

----------Product Details-----------

1. [ Vibration Screen Part ]

The linear vibration screen is run by double vibration motors of Italian brand. Free from maintenance. Front and rear gate, pull-insert installation of mesh, easy to replace.

2. [ Burner Part ]

The low-pressure burner is designed for the dryer drum with digital control on air/oil ratio and frequency, to ensure the better flame as per drum, to reduce oil consumption greatly. The burner control is integrated with plant control, easy to operate, safe and reliable. Suitable for diesel, heavy oil and natural gas.

3. [ Dryer Drum Part ]

The unified design of dryer drum, burner and bag house. The heat insulation is by silicate aluminum fibers, effective and environment-friendly.

----------Environment Protection-----------

1. Total dust collection with 1st-level inertial collecting, 2ND-level bag house and dust collecting modules for various portions of facilities.

2. We establish environment protection concepts according to the European standards to achieve in dust emission, acid emission and noise control, etc.

3. The facilities are in green harmony with the environment wherever we go.

---------- Packing Shipping -----------

------------- Our Service-----------

Technical material, warranty and free service:

1. We will offer the buyer free trainning for their operator and maintenance worker, and also provide free technical advice services;

2. And company will organize technology training courses regularly, and give free training the buyer's operator.

Spare parts supply services in time:

Our company offer the original, authentic,quality spare parts for the machine maintenance accessoriesa.

Installation and commissioning and the acceptance:

1. Our company will offer the buyer free assistance of the equipment installation, commissioning for one time;

2. Each unit after installation will have returning visit by specialized departments;

------------- Fair Show -------------